Transmission Rebuild

This page will run through how to

rebuild a three or four speed small frame transmission from bare cases.

- A hammer

- A socket or other type of drift with

a hole in the center.

- Circlip pliers

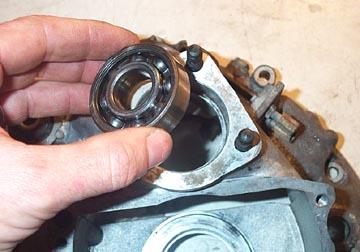

The images below show the cases without

bearings so the first step it to drop the bearings back in. I removed

these to give them a good cleaning with gasoline and compressed air and

they were good enough to reuse.

Flip the clutch side of the casing over

to show the rear wheel bearing hole. This bearing is a tight fit in the

casing and must be hammered or pressed in to place. Make sure the

casing is well supported below, preferably on wood blocks so there will

be no damage to the gasket faces.You can heat the casing up to make it

easier but usuaully it isn't necessary. Place the bearing squarely in

the hole...

...and use either a socket or some other

solid round piece as a punch and use a hammer to hammer the bearing in

to position. You'll hear a different sound when it is all the way in,

or you can flip the casing over to see if it is against the cast lip on

the inside.

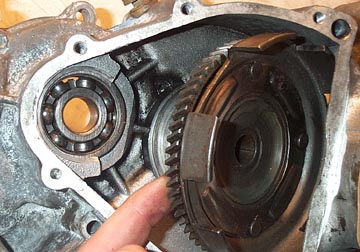

The main clutch bearing is much the

same. It goes in from the clutch side and is retained with a circclip.

If possible, find a socket or something similar that rests on the

outside race of the bearing - that way you are not hammering on the

interior race.

Once the bearing is all the way against

the lip, use circpli pliers to place the retaining circlip.

The flyhweel side of the casing also has

two small bearings. These are also hammered in to place with a flat

block of metal so that the outside face is flush with the casing.

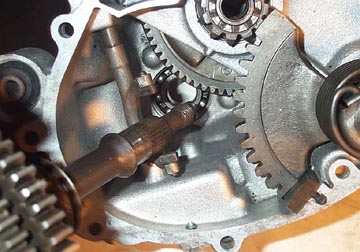

In the shot above I have also installed

the main crank bearing in the clutch side of the casing. This is very

similar to the clutch bearing and is retained by a circlip on the crank

side face. The clutch basket is a tight fit but the center of the

clutch must go through the clutch bearing. It does fit without force so

take it easy as it is easy to jam it.

Flip the casing over and make sure the

clutch basket is pushed all the way through the bearing. If it is there

will be a small groove visible just inside past the bearing. Fiut the

retaining circlip here to hold the basket in place.

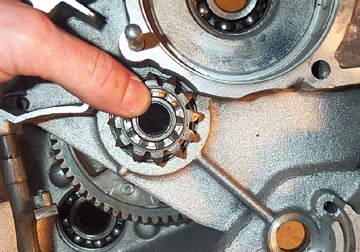

This is followed by a dished washer. The

washer goes on with the higher center part facing away from the clutch.

This is then followed by the kickstart spring which is also larger at

one end than the other. The large end faces the clutch.

Finally this is followed by the small

kickstart gear. The gear is flat on one side and has teeth on the

other. The teeth need to face outwards, away from the clutch, so that

they can engage with the transmission. The gear may try to spring off

the shaft in the next section but it can be put in place after the

kickstart layshaft is in place if you prefer.

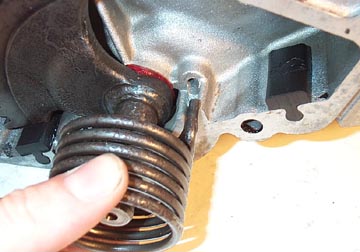

Now is a perfect time to replace the

kickstart rubber buffers which slot into the casing. Have a look

through the hole where the kickstart quadrant goes. There is a small

O-ring inside the hole which you can replace if your bike was leaking

oil around the kickstart before the rebuild. Place the large metal

spring on the kickstart shaft and make sure the hook end is slotted in

to the quadrant and the end with a straight "peg" on it is facing

towards the casing. Add a thin film of grease to the quadrant and slide

it through the casing.

As you slide it in make sure the "peg"

goes in to the hole in the casing as shown above. If the kickstart is

correctly installed it should hold the small kickstart gear on the

clutch shaft in place - see below.

The next step means that the rear hub

backplate will have to be either temporarily or finally installed. The

reason is that it stops the rear wheel bearing in place much like the

circlip on the clutch bearing. I just bolted mine in place with no

gasket to hold the bearing in place before hammering the main axle and

gear cluster in to place. Take the gear cluster and place the axle

through the rear axle bearing. Before you push it in, make sure the

gear selector is pulled as far towards the rear wheel (i.e. first gear)

so that the grooved part of the selector is furthest away from the

gears.

Carefully get the two small 'ears" of

the shifting mechanism to engage in to the groove in to the shift

cross. Be sure that both the top and bottom ears engage properly.

Use a piece hollow tube or a socket over

the end of the transmission shaft to hammer it in to the bearing. DO

NOT hammer directly on the end of the shaft as this is the area that

rotates in the bearing in the flywheel side of the casing. A socket or

hollow tube around this area works well because it rests only on an

area that is not in contact with any moving parts. As the axle pushes

through the bearing you may find the gear hit the kickstart quadrant.

This is beacuse the kickstart may have moved out of the casing but it

can easily be pushed back. You can look through an opening in the gears

near the kickstart to see when the lip on the axle is flush with the

inside of the bearing.

|