|

|

|

|

|

|

|

||||||||||

Vespa KitsSmall Frame: Large Frame: Installations: Polini 130 Porting |

Vespa Small Frame - Polini 130 InstallThe Polini kit, like the Malossi can be bolted right on to the casing, but to get its true potential the crankcase mouth transfers need to be opened up and matched to the barrel. To do this the engine needs to be stripped, the crank removed, and all the bearings should be removed.

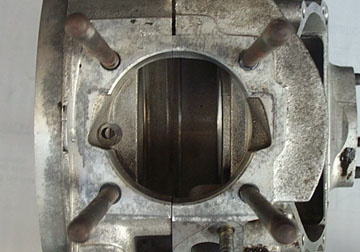

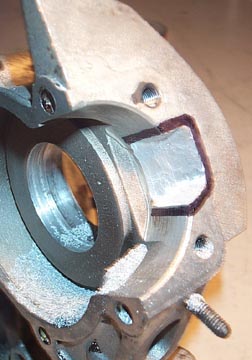

Above is a shot of the crankcase mouth

of a typical small frame case. The Polini kit I got was previously

installed on this engine block without the ports being matched and you

can see an outline of where they hit on the mating face. The original

transfers are small and angled away from the exhaust port. The flywheel

side has a small oil hole to get oil from the primary compression area

into the flywheel side bearing.

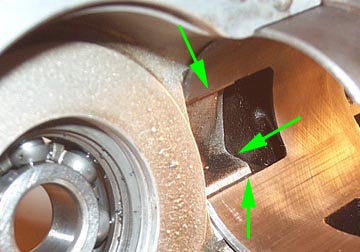

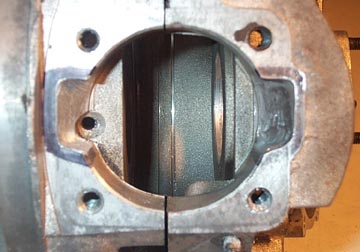

To get an idea of the metal that needs

to be removed, I slid the Polini barrel down over just the crankcase

side to see how much would have to be removed to match the transfers.

The Polini has a wider spigot cut out so the walls of the existing

transfer have to be opened up, and there was also a shelf between the

casing and the barrel transfer.

Dry fit the barrel on to each crankcase

half separately, and use either a pointed scriber or something else

sharp to scribe the shape of the barrel transfer onto the casing gasket

face. Once you have a thin scribed line, it makes it easier to see if

you use a marker to properly mark out the area to be removed so that no

mistakes will happed later. Repeat this process on both sides of the

casing.

Using a Dremel or air power die grinder,

start slowly removing the aluminum from the transfer. It is always best

to start with the flywheel side transfer as it is the more restrictive

of the two. You'll need to make both transfers the same (or close) and

since the backside of the flywheel transfer is against the stator no

aluminum can be added for more thickness to work with. Start slowly and

constantly feel the thickness of the metal to make sure you don't blow

through the casing wall.

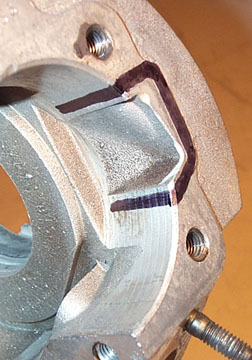

There is a fair bit of material to

remove to match the casings...and unfortunately on the backside of the

clutch side casing there is very little "meat" to work with. Without

modification, you could hardly open the transfer out without blowing

straight through the casing.

The solution is to take the casing to a

local welder and have them bridge the gap as shown with aluminum.

Welding cast aluminum is very specialized, so be sure whoever you take

it to knows what they are doing and doesn't go overboard. It is also a

good idea to leave the closest barrel stud in place so that the holes

are not distorted by the heat. Once the welder has filled the gap you

can move on to the porting work.

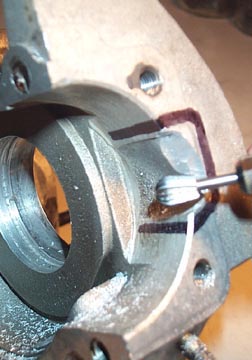

Scribe and mark the transfer the same

way as the flywheel side.

Using the Dremel, start slowly on the

clutch side using the same tips as before. The aluminum cuttings are

the reason for stripping the casings. If these get inside a bearing

they can definitley be destructive.

The final look of the transfer should

open out towards the gasket face and taper away as it goes down the

spigot opening. Always work slowly and make sure there is sufficient

metal thickness between the transfer and the backside of the case. The

above shot shows the rough transfer before blending and polishing it

out.

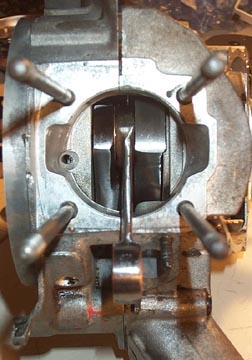

The above shot shows the two transfers

after rough shaping. The next step it to make sure they are very

similar looking to each other, and then use fine grit emery paper to

smooth them out along the ground face. Once all this is complete you

are ready to start rebuilding the motor with the new kit.

Before the crank

was installed I did a final polish of the transfers to make them

smooth and less rough than the previous picture. Once the crank is

installed you can move on to the top end. The kit I had came off a

running bike so I didn't have to messa round with fitting the rings. If

yours is a new kit you'll have to install the rings. A quick guide from

a standard small frame piston can be found here

and the idea is the same for the Polini piston.

At this point I took the original Vespa

cylinder base gasket and slid it down over the new transfers. I marked

the difference and opened out the transfer areas of the gasket with an

exacto knife to match the transfers beneath. Polini also sells a

special base gasket but a modified Vespa one works just as well. |

|||||||||||||||