Vespa Post 1979 Large

Frame Engine Work

|

|

Piston Install

One of the most important

parts of a well operating engine is a good piston and bore to keep

compression high and transfer that power to the back wheel. Basic

tolerances between a piston and a bore are typically 0.2mm. If you

remove your barrel and find deep scoring on the piston and bore it is

definitely time for a new piston. Pistons cost between $45 and $70

depending on what bike you are buying for. Whenever a new piston is

installed it is important to rebore the barrel to the next oversize if

there is major scoring of the surface, or at least hone it to be sure

that the wear ridge at the top is removed. The one pictured is from a

PX150 motor. The following images show the piston replacement after

removal of the old barrel and piston, and in these images the engine is

out of the frame but it is not a requirement.

- A piston kit

- A rebored or honed barrel

- Some two stroke oil

- A new barrel base gasket

- Circlip pliers

- Possibly a new small end

bearing

- A set of feeler gauges

A piston kit comes with two

rings, a wrist (or gudgeon) pin, and two wrist pin circlips. The first

step is to be sure that the ring diameter is correct for the bore of

the barrel. The barrel must be rebored or honed to get a uniform

surface on the bore. Piston tolerances can differ slightly and when a

ridge at the top of the barrel may be present at the upper range of the

piston ring travel. If you simply replace the piston it is possible

that the new piston maybe slightly taller and the rings can strike the

ridge and fracture.

Take either one of the rings

and fit it as squarely as you can in the top of the barrel bore. When

the rings get hotter they expand and it is critical to be sure there is

enough room for expansion otherwise there is risk of a seizure.

With the piston ring in the

bore slide the piston down in the bore skirt first. This will push the

ring down in the bore and keep it square to the diameter of the bore. I

usually push it down until the wrist pin hole is about central with the

top of the barrel.

Remove the piston and get out

a set of feeler gauges. The minimum ring gap is 0.2mm. Measure this gap

by fitting a feeler gauge in between the ring ends. If it is less than

this you will need to remove the ring and use a very fine file or

sandpaper to slightly increase the end gap. Once you are happy with the

gap, slide the piston down as you did before and push it through the

bore to remove the ring. Check the second ring in the same manner.

Have a look at the piston and

look at the ring grooves. In each one there will be a ring peg set in

the upper surface of the groove. Look at the ring ends and you will see

that there is a special cut out in the ends to go around this peg.

Carefully stretch the rings one at a time over the piston and into the

grooves making sure the ends fit into the ring pegs.

This motor had a very loose

small end bearing so I replaced it. At $5.95 it is a safe precaution

when rebuilding the top end. Vespa crankshafts are marked with one to

four score lines on the end of the con rod which note the inner small

end diameter. Basically for some strange reason these are reversed. If

you have 1 score you need the 4th oversize small end, 2 scores = the

3rd oversize, 3 scores = 2nd oversize, and 4 scores is the ist

oversize. Your scooter dealer will be able to set you up with the right

bearing if you tell them the scores or show them the crank.

Look at the top of the new

piston. There should be a mark "SC" with an arrow pointing away from

the center of the piston. This shows where the exhaust port should be

when the piston is correctly installed. The exhaust in all large frame

engines faces down out of the barrel. Slide the piston over the end of

the con rod with the small end bearing installed. You may need to heat

the piston with a hot rag before sliding the wrist pin into place, or

it can be drawn through with a bolt if required. Most new pins will

just slide right in without too much force.

Using circlip pliers, fit the

circlip to either end of the wrist pin. These can go in any way round

but they must drop fully into the groove. Remember that there is a

circlip required at both ends of the pin.

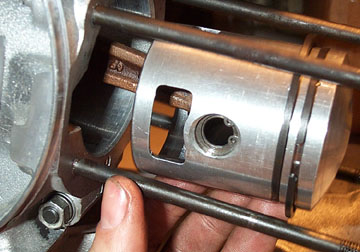

Above is a shot of a piston

with the circlips installed correctly.

With the piston installed

correctly, you can slide the thin metal base gasket down over the

cylinder studs. A 200cc motor has a different base gasket than the one

shown. The P125X and P150X share the same base gasket as shown above.

With the base gasket in place

you can move on to installing the barrel. Smear some two stoke oil

around the bore of the barrel to help with the installation, and

provide some lubrication when the bike first starts up. Carefully slide

the barrel down until it meets the piston. This is were things get a

little tricky and it helps to have a helper to help compress the rings.

Basically you need to compress

the rings into their grooves so that the ends hit the piston pegs. This

would be pretty easy except that there are two rings to do and the

barrel tries to slip off the piston whenever possible. Use your fingers

to compress the rings and then slip the spigot over each ring at a

time. Once the barrel slides down make sure the piston is travelling

freely by rotating the flywheel while holding the barrel down.

Rotate the piston at least one

full revolution to be sure everything is working smoothly.

Clean out the existing

cylinder head before installing it. Wet dry sandpaper or valve grinding

compound works well to polish the surface after any obvious carbon

deposits have been removed. On a 125 or 150cc engine can be installed

in any direction, but the correct direction is with the spark plug hole

up when looking at the motor from the front.

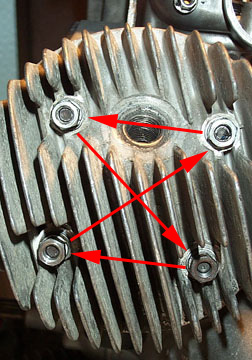

Fit a washer, lock washer ,

and nut to each stud and hand tighten them down. In order not to warp

the head, the nuts should be tightened only about 1/2 a turn before

moving to the next nut. The final torque for 125cc and 150cc motors is

xxxx, and for 200cc motors it is xxx. Finally, fit the spark plug,

cylinder shroud connector nut, cylinder shroud, and start the motor up.

For the first 300 miles you

should drive very carefully, do not over rev the motor, stay at low

RPMs where possible, and vary the engine RPM when stuck in any single

gear because of road conditions. Breaking in a piston carefully is the

best way to ensure long life from your top end.

|

|

|