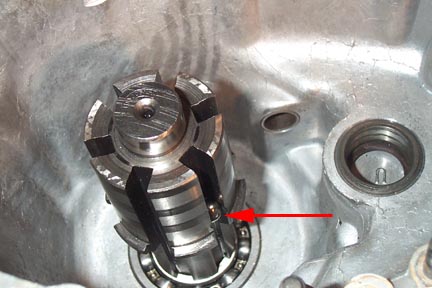

The way the spider stays where

it should when you are driving is by a single spring and two ball

bearings on either end. The spring runs through the hole in the axle

you marked earlier and the ball bearings are forced into notches on the

spider legs. As you change gear, the spider starts to move, the ball

bearings are forced against the spring, and then they pop back out into

the next notch in the spider leg. The bottom side of the spider has two

legs that are bevelled unlike the others. These are to aid installing

it over the bearings which are trying to move out.

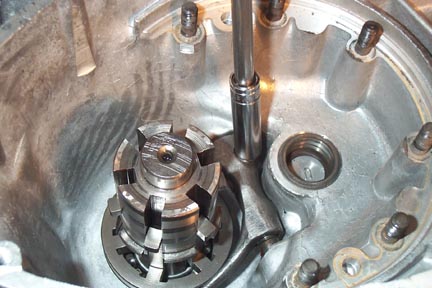

To fit the spider you first

need to set the spring into the axle hole, and the two ball bearings on

either end. Use a little grease if necessary to hold them in place.

Place the spider on the shaft

making sure the bevelled leg ends are in the same grooves as the ball

bearings. Then push down hard and it should compress the ball bearing

spring and drop firmly in to place. I always leave the spider in the

first gear position for reasons that are clear later on if you have an

all in one external actuating arm. This means that the spider legs are

flush with the thick part of the axle as shown above.

The selector arm can now be

loosely fitted to the spider. It has two small rotating blocks on the

end, which slide into the groove in the spider. Make sure the arm is

installed so that the single bolt hole has the threads towards the rear

hub.

On the outside of the casing

above the rear wheel, slide the gear selector splined shaft into the

casing. With one hand inside, make sure the shaft goes into the

selector arm hole. Depending on your model, the selector arm may be a

single piece but the one on this casing is a two piece unit. If it is a

one piece unit you should probably fit the rear hub to make sure the

gear selector arm doesn't hit the rear hub rim when the bike is in

first gear. If it is a two piece like the one shown above, the arm will

be adjustable and you can fit it so it doesn't hit the rear wheel

before you complete the rebuild.

Once you are happy with the

placement of the gear arm on the outside of the case, fit the single

selector arm bolt and tighten it down with a socket. I move the spider

through the gears at this time to make sure each one selects properly.

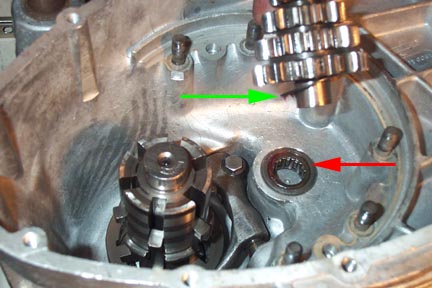

The small roller bearing (red

arrow) can now be fit into the casing followed by a small gear cluster

shim (green arrow) and the gear cluster itself. There is a special tool

to remove the metal outer which is a press fit into the casing, but

unless the play between the new roller bearing and the outer is

obviously suspect, it is easier to leave it in place. I also found a

difference between my new Indian casings which came with this piece

installed, and my old Li125 Special casings. The new casings had a

small lip which set the gear cluster further off the casings. I was

worried this would misalign the free gears and the gear cluster but it

ended up not being a problem. After asking a few questions I found that

once the clutch is installed the gear cluster shaft is pulled tight to

the gearbox end plate anyway, and doesn't really ride against this lip

- the bearing is just there to locate it and spin.

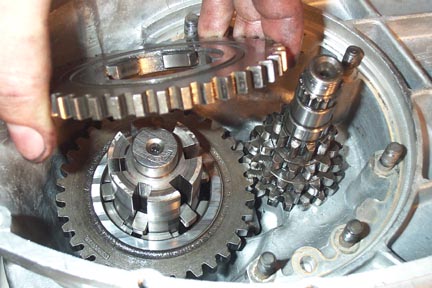

Now start adding the free

gears in the same direction you took them off. Make sure each gear

interfaces well with the gear cluster. You may have to rotate them

slightly to drop down over the shifting spider.

Fit first gear with the kick

starting ring facing you. This is followed by a new axle bearing shim,

and the new roller bearing at the end of the shaft. Once these are all

installed, fit the single large gearbox shim which fits in the groove

at the inside of the first gear piece (not shown installed, but it goes

where the blue arrow notes). This shim may need to be replaced later

with a thicker one, but unfortunately the only way to tell is to build

the gearbox and then measure the tolerance.

The gearbox backplate has a

pressed fit ball bearing which supports the end of the gear cluster.

Have a look at your bearing and see if it worth it to you to replace

it. Since I was building a non-stock motor I replaced mine to be safe.

To replace the bearing, remove the retaining circlip and bang the

bearing out from the other side with a suitable sized socket. To

install the new one, flip the backplate over and bang the new one in

until it is flush with the inside lip. Refit the circlip and the back

plate is ready to install.

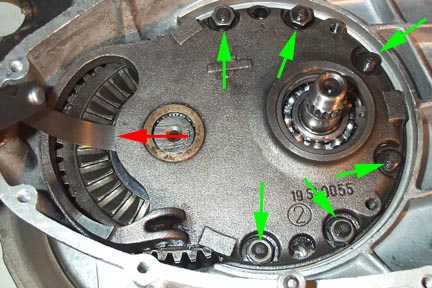

Before fitting the backplate

make sure you have remembered the small roller bearing at the end of

the rear axle shaft, and the important gearbox shim. Then carefully

lower the backplate into position and push it down until you can see

enough thread on the six casing studs (green arrows) to get the nuts

started. Fit lock washers to each stud and then add the nut. Start

tightening the nuts one at a time and only about a turn at a time. You

are trying to set the backplate down so that the backplate bearing is

forced onto the gear cluster in a level manner. As you tighten the nuts

check to make sure the backplate is moving equally down on each side

and that it is not racking in one direction or another.

Once it is fully down, tighten

all the nuts and either fit the rear hub and tighten it fully down, or

fit a small spacer tube instead of the rear hub and also tighten it

down. This is required because it makes sure the rear axle is

absolutely tight against the bearing, so you can get an accurate

reading of the shim tolerance noted below. Now get a set of feeler

gauges to measure the tolerance between the backplate rim and the

gearbox shim. Be sure you are getting the feeler gauge right in against

the backplate rim where the red arrow is shown above. Anywhere between

0.30 and 0.07mm is within tolerance. If it is beyond this range you

will have to remove the backplate and fit a thicker shim. Unfortunately

the only way to measure the tolerance is with the backplate totally

torqued down, so this may be a frustrating process. I usually have a

couple of difference thickness shims on hand (these can be ordered from

your scooter shop), and once I make the first measurement, a little

math can work out the one you need.