VespaAutomatic ProjectTransmission Rebuild |

Transmission Rebuild

Although I did open up the

casing transmission to have a look, I decided to leave it alone and see

how it works once the motor is started. The belt transmission was

another story and I needed to rebuild it partly so I could clean it all

up and party because I was curious.

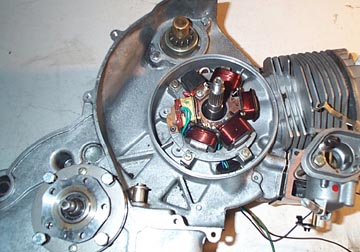

The first item to be installed

was the stator. I rewired this because the wires were so brittle and

the insulation was cracked in many places. I also marked the case and

the stator when I removed it so I simply lined them up when I

re-installed it. When the motor is running I'll use a strobe to make

sure it is accurate.

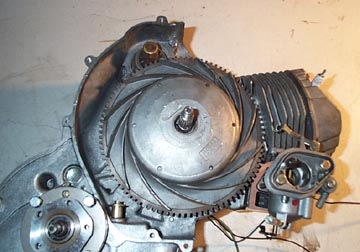

Fit the small woodrfuff key

and place the flywheel over the end of the crank. The strange thing

about this motor is that it has no flywheel nut until after the drive

pulley has been installed.

Then the throttle linkage

should be connected between the cam near the flywheel and the carb.

Since I forgot to do this I had to go back and do it later..... Install

the fan shroud and use the 6mm screws to fasten it down.

Now I switched over the bottom

pulley. The drive bell to the clutch goes on first.

Make sure the two screws in

the axle stub align with the two cut outs in the bell. Then also make

sure the holes align between the bell and the axle stub plate .

Fit the four bolts with spring

or lock washers and tighten them down with a 10mm ratchet.

Next, fit the automatic

clutch. I cleaned the clutch as best I could because finding new pads

for this seems impossible. Luckily the pads I have on this clutch have

a thick layer of friction material on them so they won't need to be

replaced for a while.

Carefully rotate the clutch so

that the five bolts line up with the plate on the end of the drive axle.

Fit the wheel side of the

lower drive pulley and line the bolt holes up with the clutch center

below.

The upper drive pulley and the

belt need to be placed next. In order to get more play in the belt, I

pushed the two pulley halves apart and wedged the belt between them.

This makes it easier to install the lower pulley.

There should be enough slack

in the belt that it can clear all the bolt holes at the lower pulley.

Fit the other side of the

lower drive pulley and try and align the bolt holes once again. It

doesn't have to be perfect as the belt might make things tilt a little.

Fit the split locking washer

and central nut to the center axle stub. I used an impact wrench to

tighten this nut since I didn't have the holding tool. Another option

would be to have a helper hold the pulley and crank it as hard as you

can with a socket. Now fit the five small bolt tubes around the central

nut.

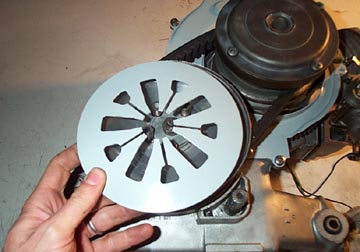

The lower drive pulley has a

very basic outer cover that acts as a spring trying to pull the pulley

halves apart.

Place it in the drive pulley

recess so that the five small bolt tubes are aligned with the

rectangular cut outs in the cover.

This is followed by a dished

central plate. Install it with the lip facing in, fit the 5 bolts, and

tighten them down equally going about a 1/2 turn at a time. You may

need to use a small screwdriver to align the bolt holes with the axle

stub if things have moved slightly.

Now that the lower pulley is bolted down, return to the upper

pulley and fit the sinle flat washer down into the central hole.

Follow this with the long flywheel/drive pulley nut and

tighten it down. This is very important to get tight as it holds the

flywheel and the pully on the crank. I used an allen head scoket driver

attached to an impact wrench because I didn't have the correct holding

tool.

The final step is to add the

cylinder shroud and kickstart So far I have decided not to fit the air

box around the carb, but we'll see if I can fit it in the frame when

the motor is test placed. I have recently found 2 suppliers of the correct belt for this model thanks to an email:

Next Section --> |

|||||||||||||||||