Electric Start??

Let me first say that there is every

possibility that this may not work at all. I got this idea after

working with my VBA electric start bike and seeing how simple the

system was. As I was thinking it over a company called ScootRS in

Vietnam came out with a system and it got me motivated to get this

project off the ground.

I want to use a standard starter that I

know can turn over a 200cc+ engine without too much effort. The PX200

(above) uses a starter with a 90 degree change to a bendix gear that

extends off the drive shaft. I took the one off my VBA and tried to

place it under the Lambretta crankcase but the design made it stick far

too low and I was worried about ground clearance.

Looking through old scooter manuals I

found an image of a small frame PK125 electric start which used the

same extension gear but was in a direct line with the motor (shown

above). I managed to score one off Ebay for only $8.00. Using an

existing Vespa motor means if there are ever any problems I can order

any of the parts, or a whole new motor without any hassles.

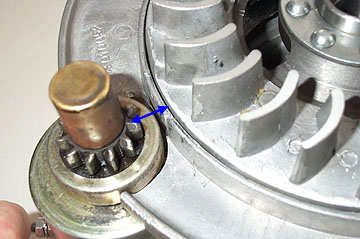

Above is a shot of the extending gear

which raises as the motor is turned. It has enough travel to engage

with a flywheel mounted ring gear when activated, and then drop down

after the engine is turning.

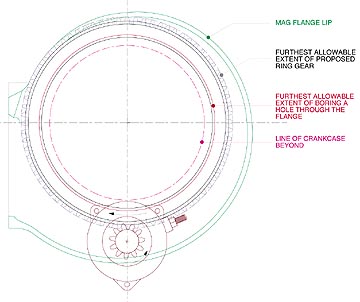

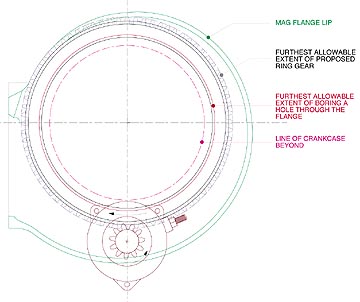

The plan is to cut a hole through the

bottom of the mag side flange so that the gear can pass through and

engage with a machined ring gear which will be attached to the

flywheel. I bought a second mag flange to experiment on so I should be

able to get the placement correct. I have also drawn up a diagram of

how I think the motor will fit against the mag flange. Click on the

diagram below for a 2 page .pdf of the idea. Please note that I

have not tried this yet...it is just to be used for interest and may

not fit like it is shown.

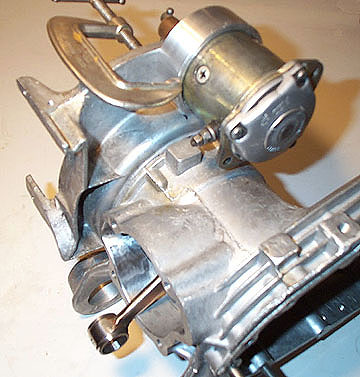

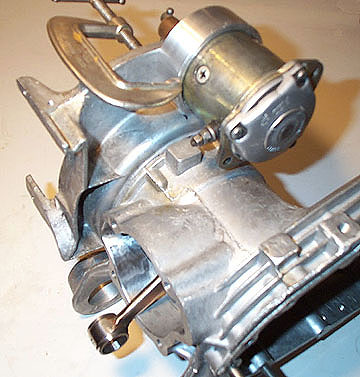

Below are a couple shots of the motor

placed in line, but with the mag flange not yet cut to allow the gear

through. These shots are of the bottom of the crankcase just in front

of the rear wheel. I'll update this page as things come together.

October 2002. I

finally had some time to work on this project again, and I took it as

far as I can go before welding. I cut a section out of the mag flange

and got the starter as close as I could to the flywheel. Unfortunately

I'll still need to fabricate a ring gear which has about a 1/2" larger

diameter than the flywheel which could create some clearance problems

at the top side of the mag flange.

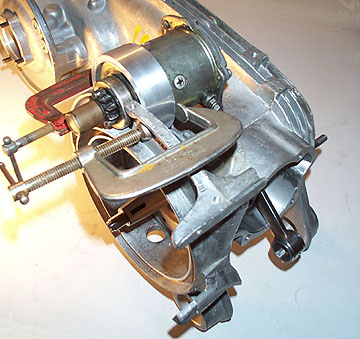

Above is a shot of where the starter

motor will be placed. I still need to have a retaining collar with an

internal diameter of the starter motor welded onto the mag flange to

hold it in place. The space between the bendix gear and the flywheel

will be bridged by a larger ring gear. In the picture below you can see

how far the ring gear will have to span (blue arrows).

Next, I had to

find a way to mount the starter to the mag flange. I found that the

starter motor has a 0.5mm shoulder about 1.5cm from the face of the

housing, so I needed to find some aluminum tubing with exactly a 63mm

inside diameter. I couldn't find anything so I took a 3" diameter rod

to a friend who did a beautiful job of machining it down into ring on a

lathe (thanks Kyle).

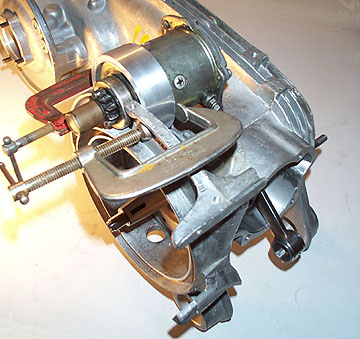

From this point I has able to cut down

the length until the tubing depth positioned the gear at the right

height in relation to where the ring gear will be on the flywheel.

This is where the collar will be either

welded or bolted into position. To get as close to the flywheel as

possible, I flattened down the mag housing flywheel wall with a file. I

would like to weld this in place, but the inside diameter of the collar

is so close to the starter motor shoulder that I am worried the heat

may distort the machined diameter. I also fitted the crank and drive

side bearing only so I could be exactly sure where the flywheel will

sit. Below are to final shots of how the starter motor will sit below

the engine casings.

I managed to get my hands on a Vespa

flywheel ring gear which I adjusted to fit the Lambretta flywheel

diameter. I needed to remove 6 teeth and then have the circle re-welded

and bent to a correct circle again. The beauty of using the Vespa gear

is that it interfaces beautifully with the starter gear on the motor.

Before I cut the teeth out I drafted the gear with 93 teeth (original)

and worked my way down to 88 teeth. Each time I cut the new gear out of

card and tried it in place to be sure before cutting the original.

I removed the Lambretta fan by drilling

the rivets out and was able to locate the cardboard cut out over the

existing flywheel base.

Above is a shot of the ring gear placed

over the cardboard gear for testing the fit. I now have to make a metal

center to the ring gear to mount it to the flywheel. Should be up and

working soon.

The final step

before building the rest of the motor was to test it out. I replaced

the bendix gear to make sure it was a good fit with the ring gear and

then fired it up with the help of a 12V-9ah battery that was fully

charged. Click to see an AVI movie

or Quicktime movie of the

starter in action.

|